The holiday season is the busiest time of the year for e-commerce brands. With the rise of online shopping, it’s more important than ever for brands to prepare for the peak season sale. In this article, we’ll discuss the steps you can take to ensure your e-commerce brand is ready for the holiday rush

Why Is peak season preparation important for e-commerce brands?

The holiday season is a crucial time for e-commerce brands to drive sales and revenue. In fact, according to Adobe Analytics, online sales during the 2020 holiday season reached $188.2 billion, a 32.2% increase from the previous year, and during the 2021 holiday season, online retail sales grew by 14.1% compared with the previous year.

With the increase in online shopping, it’s important for e-commerce brands to be prepared for the peak season to capitalize on the surge in sales. E-commerce brands must prepare for the peak season due to increased online competition and the need to meet high customer expectations to drive sales and revenue. This entails optimizing websites, offering attractive deals, and ensuring a seamless shopping experience, including timely shipping and easy returns, ultimately empowering brands to capitalize on the online shopping surge.

How to prepare your e-commerce brand for peak season sales?

Now that we understand the importance of peak season preparation let’s discuss the steps you can take to ensure your e-commerce brand is ready for the holiday rush.

1) Stock up on inventory

The last thing you want during the peak season is to run out of stock for your popular products. Make sure to stock up on inventory in advance to meet the increase in demand. Accurate inventory planning hinges on various factors, such as lead time, safety stock, planogram limitations, dynamic trends, and reorder thresholds.

Analyze your sales data from previous peak seasons to determine which products are most popular and make sure to have enough stock to meet the demand. You can also consider offering pre-orders for popular products to ensure that customers can still purchase them even if they are out of stock.

2) Ensure inventory accuracy across platforms

To ensure precise inventory and enhance customer satisfaction, deploy diverse inventory management methods. Begin by choosing a primary inventory management system, then seamlessly integrate it with various platforms.

Many popular e-commerce systems provide APIs and apps for real-time cross-channel synchronization, a critical factor for multi-location sales. For further insights on streamlining warehouse operations during peak season sales.

3) Plan your pricing, promotions, and deals

Dynamic pricing during peak sales season is a savvy strategy to boost profits. It involves monitoring competitors’ pricing for similar products and adjusting yours to stay competitive. While this may entail occasional price reductions, it can also mean increases when warranted.

Shoppers seek deals and promotions during the peak season, so plan and promote discounts, free shipping, and bundles in advance. Create urgency with limited-time offers and utilize effective merchandising solutions for pricing strategies and dynamic markdowns.

4) Prepare for shipping and fulfillment

During the peak season, shipping and fulfillment can become a bottleneck for e-commerce brands. Make sure to have a plan in place to handle the increase in orders and ensure timely delivery to your customers.

Consider a solution to help you optimize inventory distribution in a multi-warehouse network. Enhance proximity to customers, minimizing delivery time and logistics expenses effectively

Consider partnering with multiple shipping carriers to have backup options in case one carrier experiences delays. You can also offer expedited shipping options for customers who are willing to pay for faster delivery.

5) Streamline return management

Effectively managing returns is essential in the e-commerce business, especially as customers demand swift refunds and hassle-free return processes. This challenge intensifies during peak seasons, necessitating practical solutions. Utilizing software that allows sellers to record videos and streamline the SPF (Seller Protection Fund) claims process can significantly increase revenue and recoup losses from failed claims. Automate return procedures and offer convenience with curbside returns, ensuring a seamless experience for customers and retailers alike.

Other things to keep in mind

- Optimize your website– Your website serves as your brand’s digital storefront, making peak season optimization essential. Prioritize mobile-friendliness, quick loading, and intuitive navigation. Please do so during high-traffic periods to avoid slow loading, frustrating users, and losing sales. Test and enhance website performance in advance to guarantee a seamless shopping experience during peak season.

- Train your customer service team– In the high-demand peak season, a skilled customer service team is paramount. Training on products, policies, and procedures equips them to handle inquiries. Temporary staff can alleviate the workload, ensuring efficient customer support.

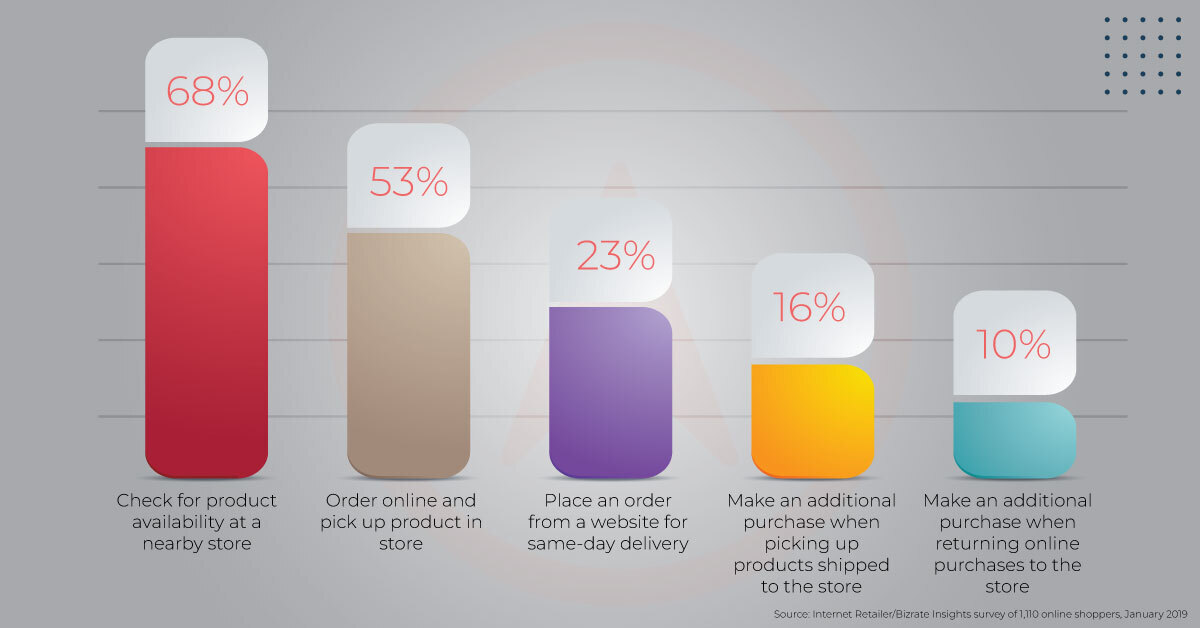

- Enable seamless cross-channel shopping behavior- Customers often navigate between online and offline channels. Only 10% start product discovery on a brand’s website. Retailers must ensure a seamless cross-channel experience, optimizing mobile apps and offering features like wishlists for in-store shopping assistance. Read more about implementing BORIS, BOPIS, and BOSS in the sales season.

- Leverage technology– Technology is a game-changer for e-commerce in peak season. Personalize the shopping experience with targeted emails, product suggestions, and custom landing pages. Leverage automation tools for predicting inventory & sales, facilitating omnichannel, tracking progress, and return management.

Real-world examples of peak season preparation

Let’s look at how some successful e-commerce brands have prepared for the peak season in the past.

Amazon

Amazon’s Prime Day, established in 2015, serves as a paradigm for peak season sales strategy. Held twice a year, this massive online shopping event features exclusive deals for Prime members, driving substantial sales. Amazon, a global e-commerce giant, excels in peak season readiness, commencing preparations as early as a year back. They stockpile inventory and employ temporary staff to manage surging orders. Moreover, Amazon entices customers and enhances sales through special peak season deals, such as the yearly Prime Day sale.

Another example is BFL (Brands for Less) Group, UAE’s leading off-price retailer for fashion and homeware. The brand was finding it challenging to manage busy warehouses and distribution centers efficiently. To discover how BFL overcame peak season challenges with Increff’s cloud-based warehouse management system.

Who is responsible for peak season preparation?

Peak season preparation is a team effort and involves multiple departments within an e-commerce brand, like planning and merchandising, warehouse management, website team, etc. However, the responsibility ultimately falls on the e-commerce manager or director, who oversees the entire process and ensures that all departments are working together to prepare for the peak season.

Conclusion

The holiday season is a crucial time for e-commerce brands to drive sales and revenue. By optimizing your website, planning your promotions, stocking up on inventory, and leveraging technology, you can ensure that your brand is ready for the peak season sale.

Make sure to involve all departments in the preparation process and have a plan in place to handle the increase in orders and customer inquiries. By following these steps, you can set your e-commerce brand up for success during the busiest time of the year.

Remember, the right technology partner can help you achieve your peak season goals and pave the way for long-term success. Book a demo today!